Wall Of Shame

Things You Can't Unsee

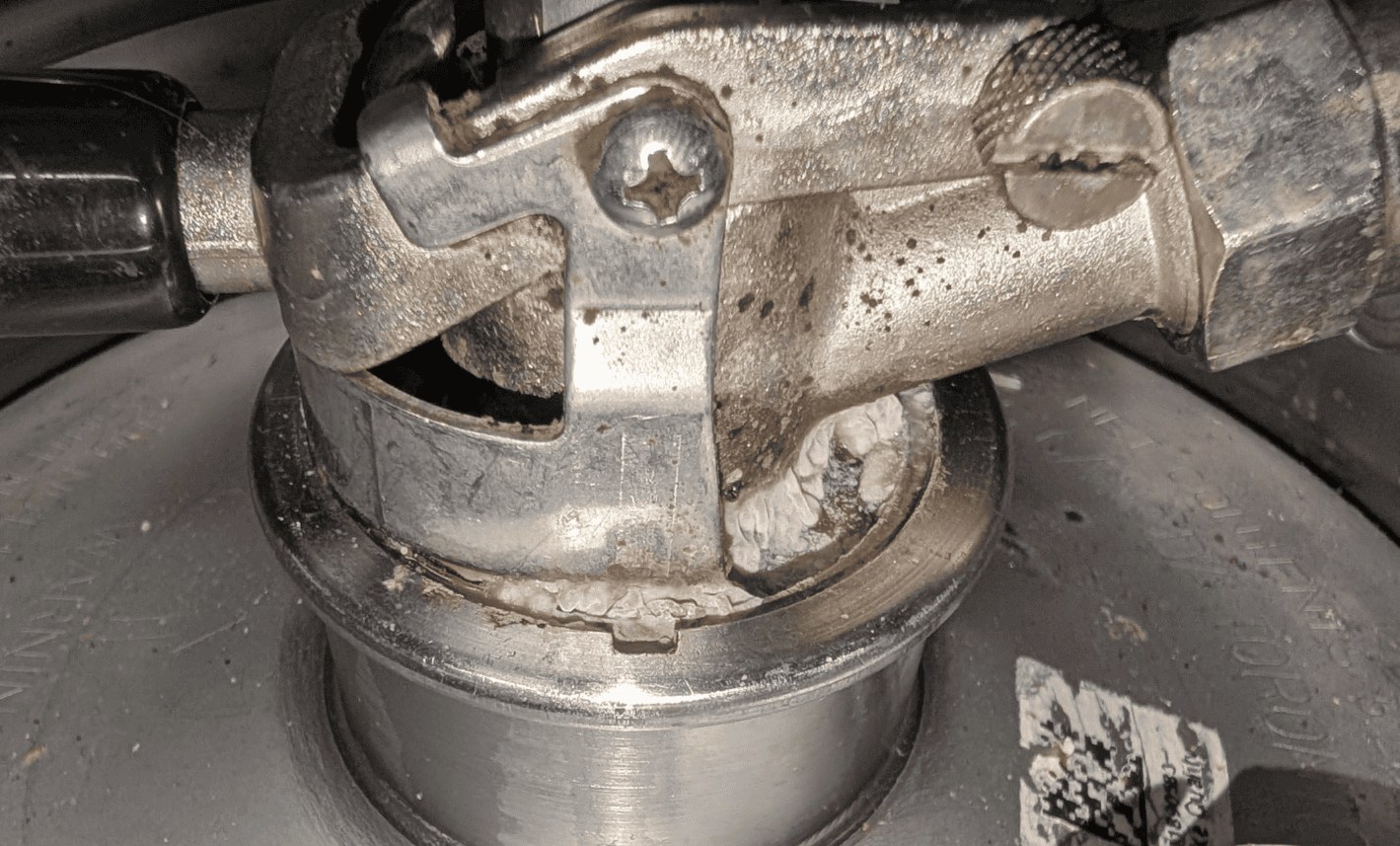

Growth On Beer Couplers

Beer couplers are the equipment that taps the keg.

They have two lines: one that sends beer gas into the keg and one that allows the beer to leave and go to the beer taps.

The first image in the gallery below is a new coupler.

This is what they should look like if they are cleaned properly during each line clean. Draught service technicians soak and scrub the couplers at each line clean to ensure no old beer is stuck to the body of the coupler. This old beer eventually turns into mould.

During keg change, this mould can fall into the neck of a new, fresh keg and end up going into the beer.

During our Better Beer audits, we check every coupler to ensure they are clean.

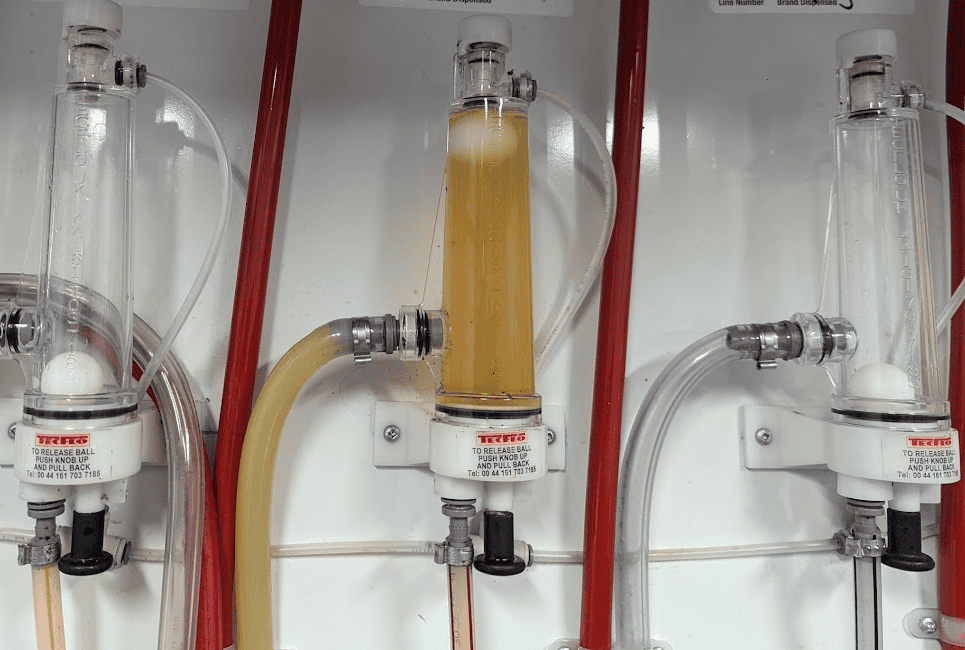

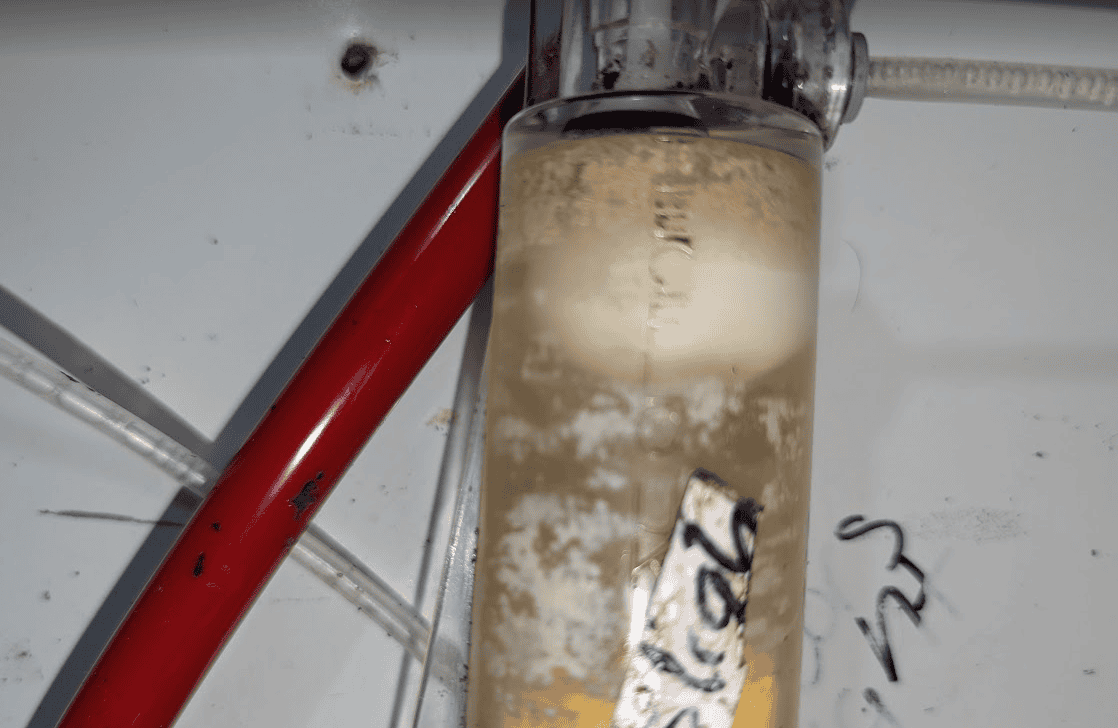

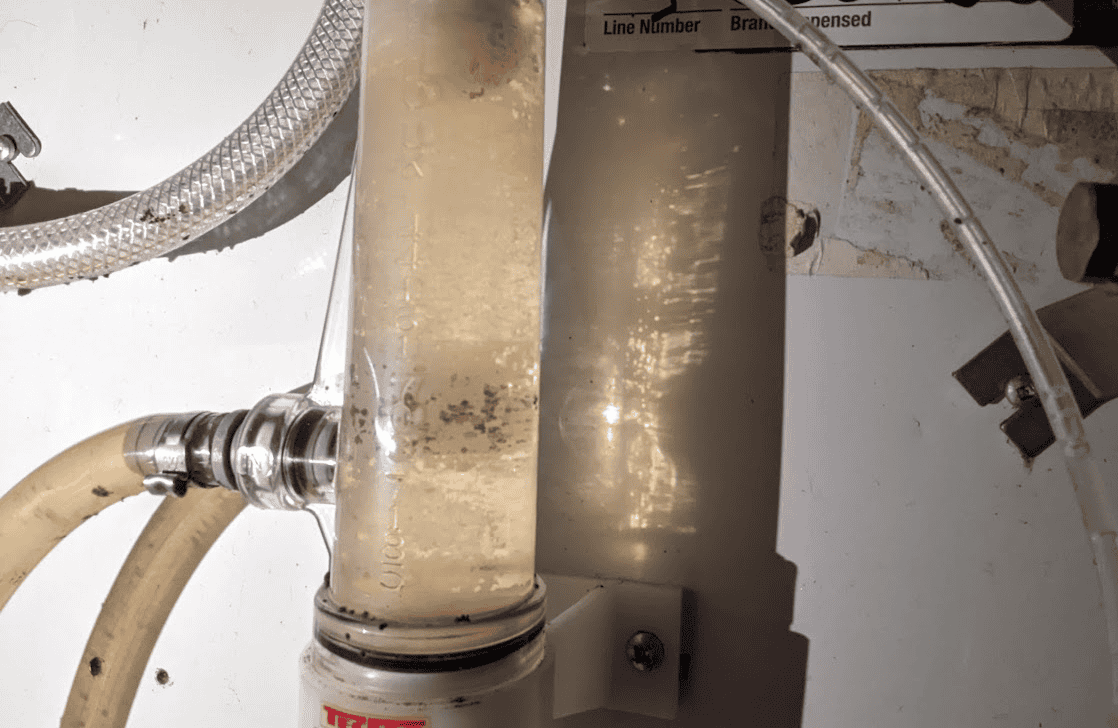

Dirty Beer FOBs

FOBs - Foam On Beer Detectors help eliminate foaming at keg change.

The chamber (tall cylinder that houses beer) must be soaked with a line cleaning solution during each line clean. If the service technician takes some shortcuts, the FOB is not exposed to any cleaning solution, and beer stones develop. Beer stones are like small grains of sand—they are actually calcium deposits.

The yeast in beer attaches to the beer stone and creates Diacetyl.

This gives the beer a slick, creamy mouthfeel and makes the beer taste like butter.

During our Better Beer audits, we check every FOB to ensure they are clean. Below, the first image is a clean FOB, 2-4 have growth/beer stone building up inside the FOB.

Dirty Beer Taps

Beer Taps (faucets) are where the beer flows from as it pours into your pint glass.

Like the other pieces of draught beer equipment, they must be cleaned regularly.

Unfortunately, it isn't always done. So when the bartender turns the tap on, that round little button-looking thing (Faucet Face) moves back and forth, and the gunk falls into your pint.

We check every tap during our Better Beer audits to ensure they are clean.

The first image is a brand new, clean faucet. The second image shows the difference between a stainless steel faucet (suggested) and a brass faucet. The third has residual beer on the outside, attracting fruit flies; the fourth has bio-film build-up inside the faucet.

Lines and Other Quality Issues

The beer travels through the Trunk Line between the beer fridge in the back to the taps on the bar. The Trunk Line should be well insulated to keep the beer cold. Unfortunately, installers cut corners, which causes warm beer.

The Bar's Management is responsible for the outside of the equipment, the condition of the beer fridge, and the glassware. It's not always up to the Brewer's standards.

During our Better Beer audits, we check the fridges, lines, glasses...everything from keg to glass to ensure it's cold, fresh, & clean.