Finding Ways To Cover Wage Increases.

Save With Better Beer.

Draught beer pours from the tap at 2 oz per second.

It costs 12.5 c per oz.

That's $1 of draught flowing from your taps every 4 seconds, $2.50 every 10 seconds.

Not all of that draught makes its way into the glass. Or sometimes, too much does.

We help you save money in draught spillage to offset the minimum wage increase.

What Is Better Beer?

We do not clean lines, sell/service draught equipment.

You do not need to change suppliers when working with us.

What They're Saying

5 Ways We Save You Money

Beer Clean Glasses

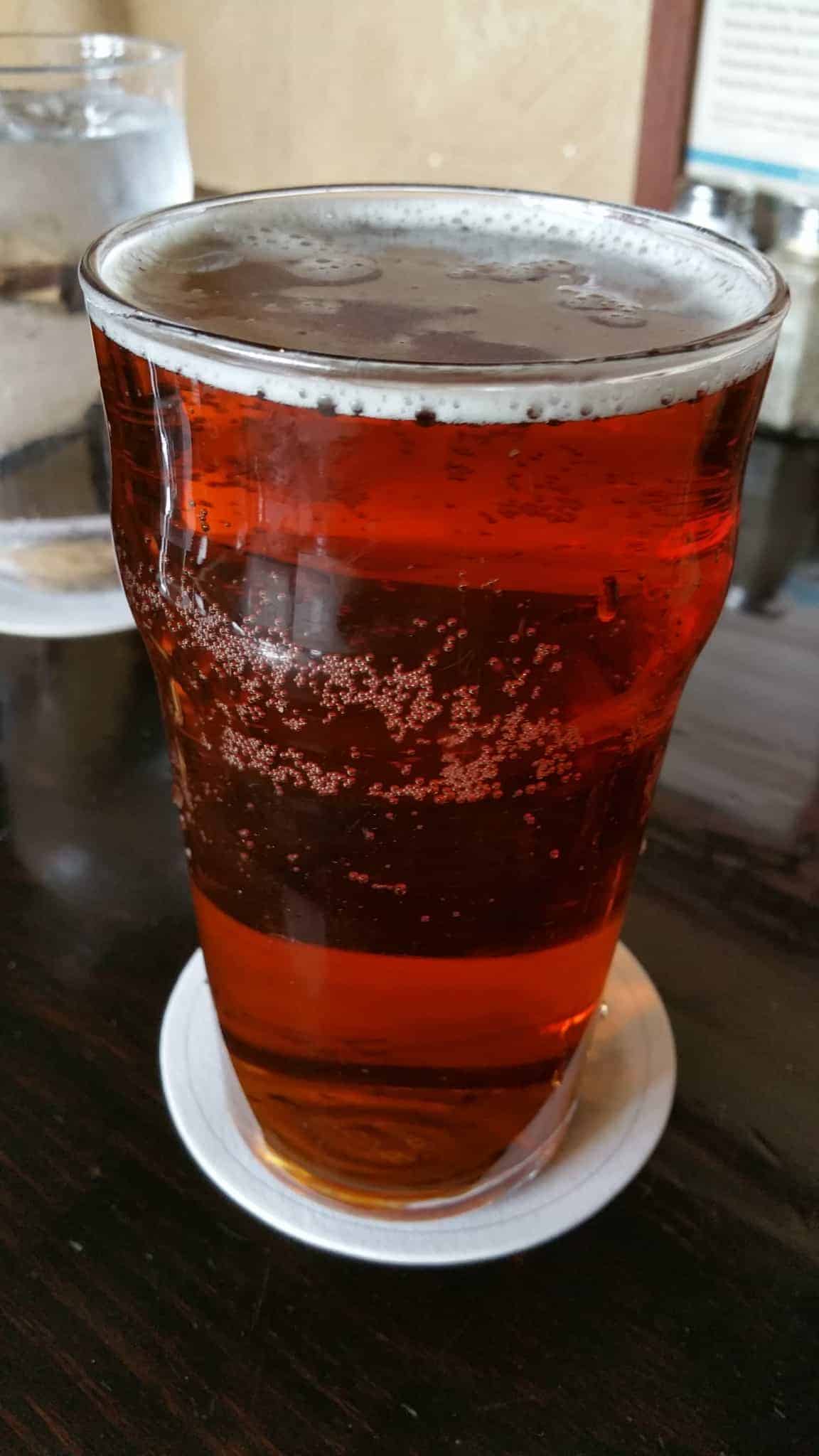

Do you serve pints like this? No head-retention, bubbles stuck on the side of the glass?

Dirty Beer Glasses are one of the biggest issues in the industry - but also the easiest fix.

Dirty pint glasses cause:

- over-pours

- returned pints from guests

- lower re-order rates

- bloated guests who drink less

Our glass cleaning kit is the fastest, easiest way to improve your draught quality. Use it in connection with your current glass washing system. Time commitment - 20 minutes a week.

Online Staff Training

The Hospitality Industry's Most Comprehensive Draught Training.

Two levels of training, that covers:

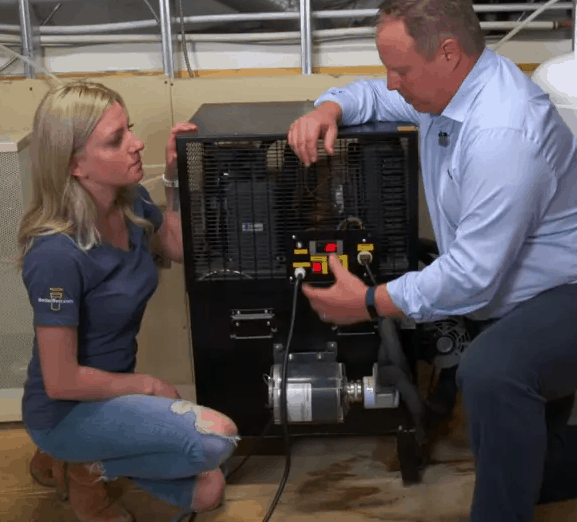

- How the system works – what are regulators, couplers, faucets, and FOBs.

- Proper storage and receiving of kegs – which kegs should you store upside down?

- How to change a keg without getting a beer shower.

- Proper pour – You’ve told them to put a head on the beer, but we tell them why.

- Beer clean glasses – when your staff understand what Beer Clean Glasses are, you make more money.

- Branded glasses – yup, they’re a pain, but they also make your life much easier, and you make more by using them.

- Using FOBs – not knowing how to use a FOB properly will waste $6 of beer at EVERY keg change.

- Troubleshooting – the system only breaks down on busy nights it seems. Wouldn’t it be great if you could solve some problems on your own and get back to selling pints?

- And…how to sell more beer.

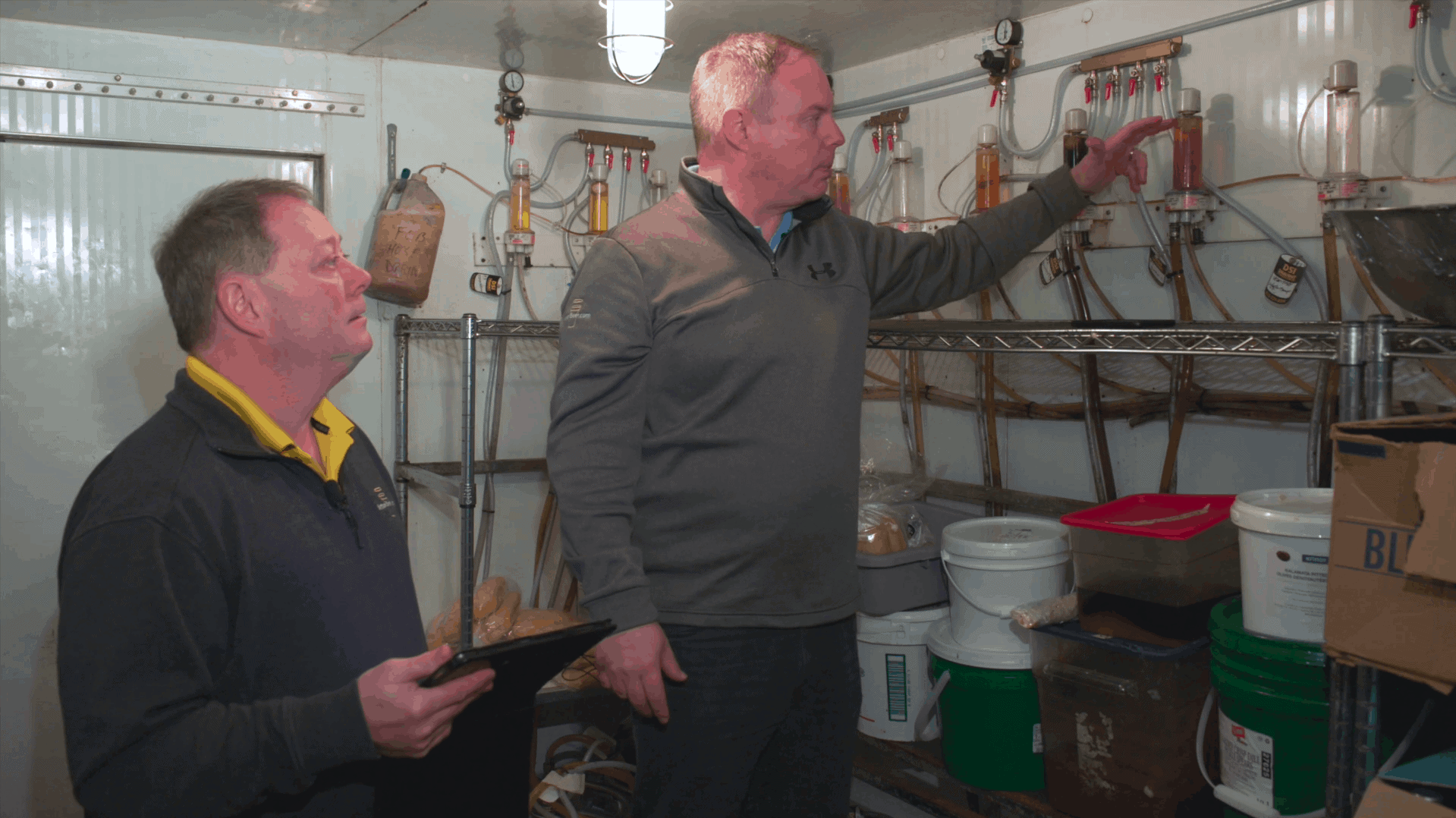

System Quality Assessment

Basically, no two systems are installed the same way. Installers have their own beliefs on what is "the best way".

Line cleaners sometimes cut corners.

Our Deep Dive Draught Quality Assessment will help you improve your system. We'll spend 90-minutes evaluating your system and provide you with a report with actionable items to improve quality and profitability.

Don't really understand how the gas system works or why your beer pours foamy for one second halfway through a pint? We'll tell you why.

How to tell if your glycol deck is about to crash and how to prevent it. What is backup gas and are you running on it all the time (a $1,800 mistake)?

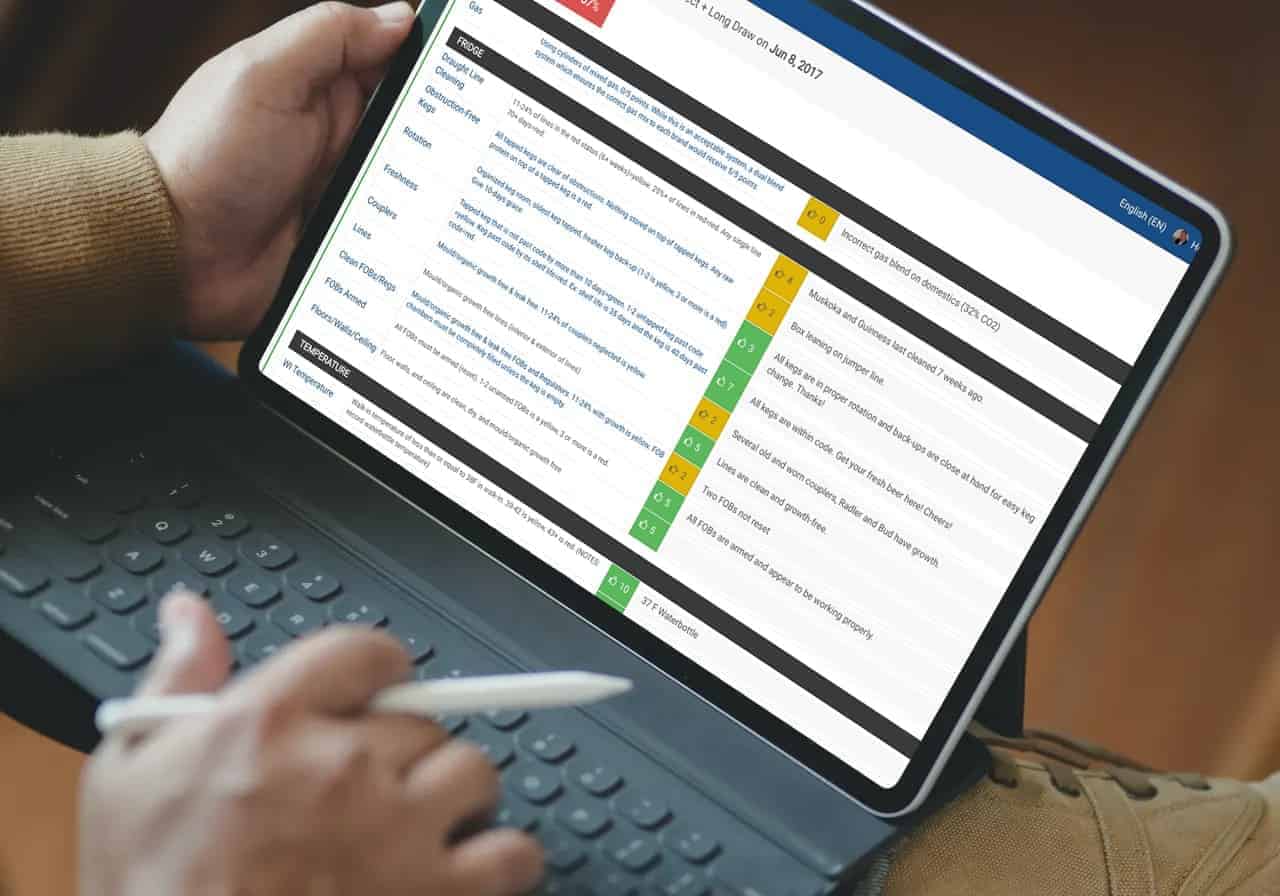

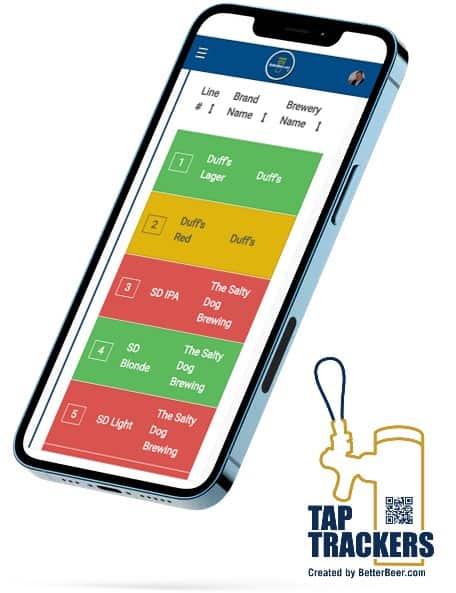

Online Beer Line Cleaning Tracking

Line cleaning has always been hit or miss.

Do you know when your lines were cleaned last or by who?

Lines should be cleaned at least every 4 weeks with a caustic solution and once every 3 months with an acid solution.

We've found that over 90% of bars in Canada don't meet this requirement. Is your's one of them?

Draught Recovery Kit

Currently, your line cleaner dumps all of the beer in each line when they clean your lines.

This adds up to thousands a year.

We've created a system to recover and sell that beer safely so you turn a $2,000 loss each year into $5,000 profit.

The Path To Better Beer

Step 1

Book A Demo

Book in a 20-minute demo so we can see if we are a fit and how much we can save you. 💰

We'll customize a plan based on your challenges and needs.

Step 2

Start The Program

We'll ship you a Glass Cleaning Kit, licky split.

Assign on-line training to your team.

Schedule a Deep Dive Audit and on-boarding for your leadership team. ✅

Step 3

Get Results

Better keg yields, fewer comped pints, increased quality and profitability.

Fewer sleepless nights. Zzzzz

And, you're proud of the pints you sell. ❤️