Trunk Lines

Your beer travels from the walk-in beer fridge to the bar through the trunk line.

Easier Shifts & Better Tips

Posted: May 13, 2018 | By: Steve Riley | Time to read: 3 min

Internet Cable

In many ways, the trunk line in your bar is like the internet cable in your house - the quality and condition of the cable will determine how fast your upload and download speeds are as well as the up-time.

If the cable is old, has been spliced multiple times, and has nics in the cable, it won’t work very well.

The trunk line is the same thing. Rips, multiple splits, old, worn insulation - your beer will be warm and poor quality.

Hand Made vs Commercially Made

The trunk line is a bundle of lines held together by several layers of different types of tape and foam insulation. Some installers prefer to make their own trunk line instead of buying it from a manufacturer where it has been assembled by a machine.

The name of the game with trunk lines is that it be wrapped as tightly as possible and each layer be completely wrapped in tape. This is very difficult to do by hand.

With the new technology and the ability of the machines to properly manufacture trunk line, there is no need to try and do it better by hand.

Professionally manufactured eight product trunk line costs about $20 a foot. Making it yourself will cost about $10. On a 100 foot run, you would save $1,000 but spend hours trying to build it.

It is not worth the time and the significant drop in quality to make it by hand.

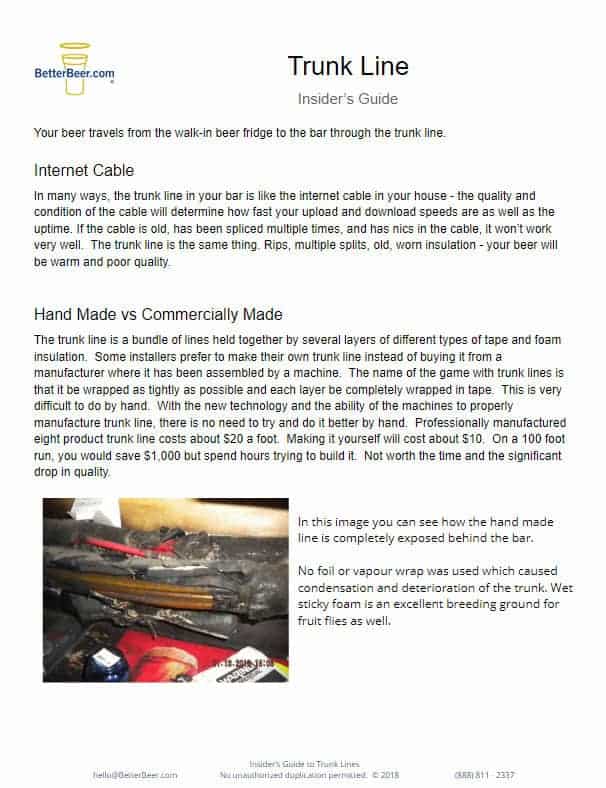

In this image you can see how the hand made line is completely exposed behind the bar.

No foil or vapour wrap was used which caused condensation and deterioration of the trunk. Wet sticky foam is an excellent breeding ground for fruit flies as well.

Getting to the Bar

A trunk line typically runs under the floor from the walk-in to the bar. When they are building the restaurant the contractors will place a large plastic tube in the floor before pouring the concrete.

This large tube is referred to as conduit. This conduit allows the trunk line to be pulled from the walkin to the bar.

If the restaurant is retrofitted into an existing space (previously a bank or retail store, for example) it isn’t always cost effective to dig a trench through the existing floor to put in a conduit.

In these cases, the trunk line runs across the ceiling and down to the bar. This creates issues as the walk-in is typically located in the kitchen and most often the line of kitchen equipment is in between the walk-in and the bar.

The installers should try to find a way so that the trunk line doesn’t run above the kitchen equipment as this will create hot spots.

Even when the trunk line runs across the ceiling in the restaurant, it becomes warmer than it should (especially in summer months) because heat rises.

In these cases, the condition of the insulation becomes very important.

Behind the Bar

If you have spent anytime behind the bar, you quickly realize that not all bars are designed the same. Sometimes the bar is designed by people who haven’t worked behind the bar or the designer is limited by structural restrictions or equipment dimensions.

As a rule of thumb, trunk lines should not run behind glasswashers. If they do, the should run on the floor not under the bar top.

If the trunk runs under the bar top behind the glasswasher, the heat from the glass washer will create a hotspot.

This hot spot will create a small pocket of foam in the line so the beer will quickly flash (beer foam beer) sometime during pouring.

This makes it difficult to pour a proper pint.

Common Trunk Line Installation Issues:

- Avoid running the trunk line behind a glasswasher. The constant heat and moisture from the glasswasher will escalate the decay of the material and create “hot spots” within the line.

- Running the trunk line up in the ceiling instead of the floor should be avoided as well. Heat rises so putting the trunk in the ceiling creates a warm environment and causes the glycol deck to work harder which burns more energy and wears out the pump and motor.

- The conduit that comes out of the floor should have a collar of at least six inches above the floor in both the fridge and bar ends. This will help reduce the amount of water/liquid that ends up spilling down into the conduit which will erode the trunk insulation.

- Some installers will run the trunk along the floor behind the bar from the conduit to the tower. Bars are wet places and if the trunk line sits in a pool of water it will rapidly compromise the insulation. Raising it at least six inches off the floor is preferred.

- Exposed, frozen cold lines (usually in the fridge) are a sign of an improper installation. Exposed chiller lines become covered in condensation which quickly freezes causing cold loss. Also, a great deal of energy is spent on keeping the ice frozen, instead of the beer cold.

Summary

All trunk and glycol lines should be properly wrapped with vapour barrier, foil tape, foam, and a black protective plastic tape.

No chiller lines or product lines should be exposed. Proper trunk line means cold beer.