A Broken Draught System

Costs You Thousands

It's Saturday night and your draught system crashes.

Nobody is answering the phone.

Nothing but foam from the taps.

Guests are angry, staff frustrated, and you don't know how to fix it.

Catching potential issues BEFORE they happen is critical to your success.

Our recurring audits ensure your system is clean, cold, and efficient while limiting downtime.

Basically, no two systems are installed the same way. Installers have their own beliefs on what is "the best way".

Line cleaners sometimes cut corners.

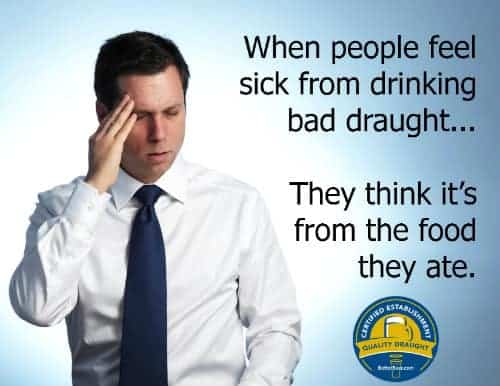

40% of your draught spillage is caused by a broken / inefficient system. 60% of beer spillage is caused by bar staff.

You don't have the time to monitor draught temperatures, date codes on kegs, proper rotation, glass washer cleanliness, beer glass cleanliness,....

You can barely keep your head above water without closely monitoring your draught system.

Then this happens...

[modula id="3253"]

We developed the industry's only brewery-neutral Draught Quality Audit. Using brewing industry standards as a base, we added in extra criteria to help you sell better quality beer than your competitor.

-

We check over 20 items on each line.

-

Customizable so you can add in extra criteria.

-

Along with the list of issues, we provide detailed solutions on how to fix them.

-

You'll get the results in real time via email and see past audits on your dashboard on our secure, password protected site.

-

We give you a Better Beer Draught Quality Score. The average first score is a 57.

We don't clean lines or sell equipment, so there is no conflict of interest; we're not going to tell you that you need something when you don't.

We have done

0

Draught Quality Audits since 2010